How to Design a Small Warehouse Layout

Blogs

Finding the right warehouse setup maximizes productivity, boosts storage safety and provides many other benefits. Understanding warehouse layouts can help you improve cost efficiency and reduce waste while setting up operations. If you’re wondering how to set up a small warehouse, use this guide to help you plan your small warehouse design.

The Function and Needs of a Small Warehouse Setup

Warehouses have multiple functions but are often used by businesses to store materials and goods before they’re delivered to consumers or moved from vendor to vendor. Various businesses utilize warehouses, including manufacturers, importers and exporters.

Small warehouses need to plan accordingly to ensure there is enough space for every function in a warehouse. Some of the main functions and needs of a warehouse include:

1. Receiving

Warehouses must have a receiving area where incoming materials are handled before they’re sorted into storage. The trucks carrying the materials, products or equipment arrive in the receiving area, where employees unload the materials and inspect them to ensure they’re ready for storage. Employees also create a record of the items received and measure the quality of products against the expectations before moving them to storage.

2. Storage

One of the main reasons businesses use warehouses is for storage. A warehouse can store materials until needed while preventing waste and ensuring the safety of your inventory. You can use a warehouse to store a broad range of materials, such as:

- Raw materials and finished goods

- Machine parts and business equipment

- Packaging items

Your warehouse should be designed to meet your business’s unique storage needs, so you’ll need to consider what you need to store in your warehouse and the best method to do so.

3. Flow

Flow is an essential part of a warehouse and refers to the movement of goods throughout the warehouse. Flow is even more critical in a smaller warehouse where congestion is more likely.

Small warehouse owners need to create strategies to ensure materials move smoothly throughout the warehouse and congestion is removed where possible. Generally, you’ll want materials to flow from one area to the next without any disruptions.

4. Packing and Shipping

Warehouses also have packing and shipping locations where materials are prepared for shipment. The dedicated packing area is where employees package materials and products, which are then delivered to the shipping location. Once the prepared items reach the shipping dock, employees load them into trucks so they can ship them out.

5. Free Space

Generally, you’ll want to have some free space reserved in the middle of your warehouse in case your business operations grow. While that space remains empty, it leaves room where employees and machinery can come and go without the risk of congestion. As your business develops, you can transform this space to accommodate new workstations and otherwise suit your growing needs.

Considerations in Small Warehouse Design

You’ll want to design your small warehouse as efficiently as possible to limit interruptions and improve workflow. There are many factors to consider in warehouse layout design, including:

- Efficiency and functionality: You need to fit inventory in ways that maximize the productivity in the space, which means reducing the risk of bottlenecks or congestion. Inventory receiving, tracking, warehouse picking and inventory shipping are steps you should consider to maximize the efficiency and functionality of your warehouse design.

- Space: You’ll need to have the exact dimensions of your warehouse available before creating your layout. When creating your design, you want to give your storage area as much space as possible. You can use modern storage equipment to store many materials in a smaller space, such as pallet racks. Smaller spaces can be allotted as offices, restrooms and other areas.

- Products or materials: Another factor to consider is the products or materials you plan on storing in your warehouse. You’ll need to consider your products’ weight, dimensions, sensitivity and perishability to decide what storage equipment you need and the best method to store different items.

- Personnel and equipment: Your staff is critical to your warehouse facility. You’ll need to account for how many people work inside your facility so you can create a warehouse layout that prioritizes safety and maximizes worker efficiency. Employees shouldn’t be clustered too closely together, or it can quickly become a hazard. You’ll also need to consider the equipment you’re using inside the warehouse. Understanding the dimensions of your warehouse can make it easier to choose the right equipment for your facility.

- Accessibility: You should design your warehouse to ensure it’s as accessible as possible — your staff should be able to find or move materials quickly. You’ll also want to consider how you store your materials when designing your layout and considering accessibility. For example, if you’re using pallets for storage, you should be able to access them easily and the materials they carry, regardless of whether they’re stacked or lined up in rows.

The Best Small Warehouse Layouts

The best layout for a small warehouse varies based on storage needs and exact dimensions. You can take the following steps to help you achieve the best design for your needs:

1. Make Blueprints

Visualizing your warehouse’s layout can ensure you can optimize the space and make changes before anything is installed. Even small warehouse owners should create a blueprint — it’s easier to plan your layout with a visualization of where storage areas and workstations will be located.

A blueprint will help you better understand the best location for your storage spaces, receiving and shipping areas and the relationship between each site. Your blueprint will also be critical in finding the best workflow to ensure maximum efficiency.

When creating your blueprint, you should have access to the most accurate dimensions and measurements, including the dimensions of your entire warehouse and the measurements of each workstation. Remember to label each item you include in your blueprint so it’s easier to reference moving forward.

2. Determine What Workstations You Need

Identifying the necessary workstations can help you decide if your warehouse has enough space to accommodate your needs and whether employees can operate comfortably and safely within the space.

The first workstation to consider is the storage area, as it’s usually the largest in most warehouses. Your storage area can be calculated by using the square footage of the entire warehouse and subtracting it from the square footage of your other areas, such as restrooms or offices.

You’ll want to account for all major locations in your warehouse apart from your storage area, including your shipping and receiving places, assembly lines, employee spaces or staging areas. Knowing what workstations you need will make planning the best layout for your operation easier.

3. Consider Different Layouts and How They Affect Flow

Your layout will affect workflow and how efficiently your staff, equipment and products move. You can choose the best format by considering your available space and picking the option that fits naturally within the dimensions of your workspace.

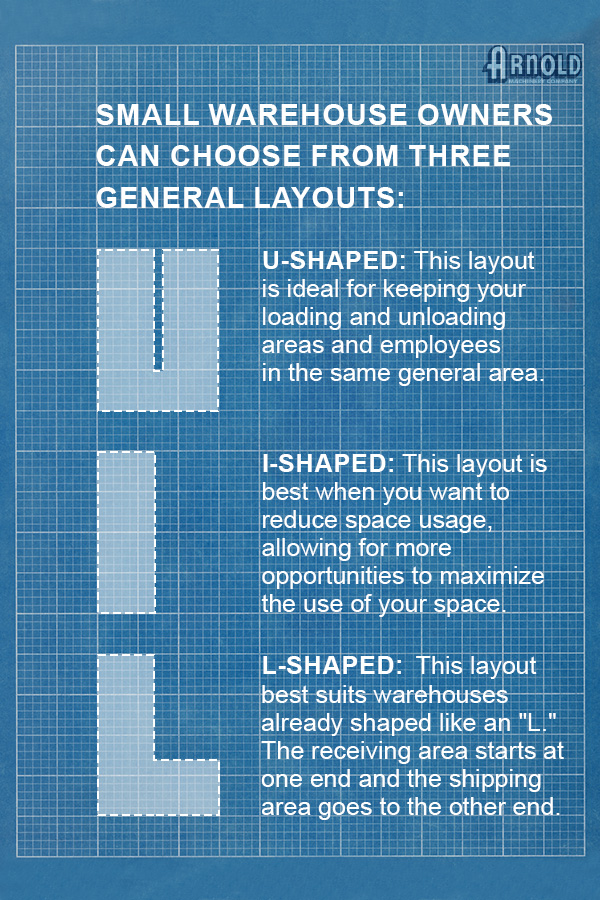

Small warehouse owners can choose from three general layouts, including:

- U-shaped: You may choose the U-shaped layout if you want to keep your shipping and receiving areas nearby. You’ll receive materials at the start of the “U,” and they’ll move through your warehouse until the end of the “U” shape. This layout is ideal for keeping your loading and unloading areas and employees in the same general area.

- I-shaped: This layout moves from one end of the warehouse to another, forming an “I” shape. This layout is best when you want to reduce space usage, allowing for more opportunities to maximize the use of your space. For example, the area you save using this layout can help you increase your overall storage space.

- L-shaped: This layout best suits warehouses already shaped like an “L.” Typically, the receiving area will start at one end of the “L,” and the shipping area will be at the end of the “L.” In between, you can set up your storage and other work areas that work best for your operations.

You can change the final layout to best suit your operations, but most small warehouses will follow the layouts listed above.

4. Test Your Plan and Ask for Feedback

If possible, you’ll want to test your layout plan on-site to ensure traffic flow is as efficient and productive as possible. You can use masking tape or other markers to indicate where each workstation will be before you install your equipment. Once markers are laid out, you can perform a mock test to see how efficiently materials and staff move throughout your warehouse.

You can also ask your employees for feedback if they participate in the mock test. Suggestions from employees can help you see new perspectives, allowing you to make changes that best suit your operations and your staff.

Material Handling Equipment Needed for Warehouses

Once you’ve determined the best layout for your warehouse, the next step in figuring out how to design a small warehouse is equipment.

Your warehouse will need workspace and storage equipment to help employees complete tasks and ensure products and materials are stored effectively and safely. The most essential equipment you’ll need is material handling equipment, which will help you move materials and products from one station to the next.

Some examples of material handling equipment commonly found in warehouses include:

- Hand trucks: Also known as dollies, hand trucks are versatile tools for moving smaller loads manually. They feature wheels and a handle, making it easy for workers to transport items within the warehouse.

- Conveyors: Conveyer systems automate the movement of items along predetermined paths, minimizing the need for manual intervention and expediting order fulfillment.

- Forklifts: These are some of the most essential pieces of warehouse equipment. They come in various types, including counterbalance, reach and pallet jacks. They’re crucial for lifting and transporting heavy loads over short distances.

- Cranes: Cranes facilitate the handing of heavy or bulky items. Overhead cranes can move large loads across the warehouse, while gantry cranes are suitable for outdoor spaces. They enhance efficiency and safety when dealing with items that are difficult to handle manually.

- Platform trucks: Platform trucks are flatbed carts with wheels designed to transport larger loads within the warehouse. They’re handy for moving items that may not fit on standard shelving units.

- Bucket elevators: These vertical conveyors transport bulk materials like grains or powders between different warehouse levels. They consist of buckets attached to a chain or belt, enabling efficient vertical movement.

- Rolling staircases: Rolling staircases provide safe access to elevated storage areas. They’re equipped with wheels for easy movement and are essential for reaching items stored at heights within the warehouse.

- Racking systems: Shelving and racking systems are fundamental for efficient storage. Selective racks allow easy access to individual pallets, while drive-in racks maximize space utilization by enabling forklifts to enter and retrieve items from within the rack structure. Mezzanines provide additional storage space by utilizing vertical space effectively.

The exact equipment you need will depend on the type of products you’re moving and the efficiency required for your operations.

Warehouse Design Solutions From Arnold Machinery Company

Arnold Machinery Company offers innovative warehouse design solutions that optimize operational efficiency and enhance your storage capabilities. Our commitment to integrity and quality allows us to deliver the warehouse solutions you need for optimal operational performance. From strategic layout planning to incorporating cutting-edge technologies and equipment for streamlining processes, we bring tailored solutions to your warehouse.

Arnold Machinery Company specializes in optimizing space utilization through advanced racking systems, automated storage solutions and efficient material handling operations. We’ll work closely with you to create designs that maximize productivity while minimizing costs. Our solutions will help you enhance order fulfillment, inventory management and overall logistics efficiency.

Our dedication to providing comprehensive warehouse design solutions translates into seamless workflows, reduced downtime and improved customer satisfaction. We empower warehouses to adapt and thrive in dynamic business environments through our expertise and commitment to innovation.

Explore Effective Warehouse Solutions

Ready to optimize your warehouse for peak performance? Contact the professionals at Arnold Machinery Company today and explore innovative warehouse solutions tailored to your needs. At Arnold Machinery Company, Customer Satisfaction is Our Only Policy®. Our dedication to your satisfaction and our Silver Service® policy ensures you’ll get the custom solution that fits your operation.

Take the chance to visit our Experience Center, where you can witness firsthand the latest technologies in action. Elevate your warehouse capabilities — reach out to us now and schedule your warehouse consultation.